Post-tensioning Design

Precision Engineering for High-Performance Structures

At Skyscraper Creators, we deliver specialised Post-tensioning (PT) design solutions tailored for slabs, beams, podium decks, bridges and complex structural systems. Our PT designs optimise structural efficiency, reduce material usage and enable longer spans with thinner profiles without compromising strength and serviceability.

We support both domestic and international projects with end-to-end design support including anchor layout planning, cable profiling, stressing sequence and construction-friendly detailing.

Our team works closely with consultants, contractors and fabricators to ensure every PT system is:

- Structurally sound and code-compliant

- Economically optimised

- Easy to install and stress on site

Our deliverables include

All our PT design documentation adheres to international standards such as PTI and Eurocode, ensuring seamless integration across design, construction, and project management teams.

Post-tensioning Design & Layout

Elongation & Stress Calculations

Anchor Zone & Profile Optimisation

PT + RCC System Integration

Comprehensive Design Report

What is

POST-TENSIONING?

Where the concrete is placed around ducts/ sheaths containing unstressed strands. Once the concrete has gained sufficient strength, the strands are stressed against the concrete, locked off via special anchor grips and then the ducts are grouted. All the tendon forces are transmitted directly to the concrete, so no stresses are applied to the formwork, thus conventional formwork may be used.

Prestressing

Prestressing is defined as the precompression of a concrete element (typically through steel wires or strands), such that when flexing under applied loads, the concrete element still remains in compression. Concrete functions best under compression and is brittle in tension. Thus, prestressing is introduced to compensate for the tensile stresses experienced by a concrete element, thereby providing a more efficient design. There are two methods of prestressing.

Pre-tensioning

Where the concrete is placed around previously stressed strands. As the concrete hardens, it grips onto the stressed strands. Once sufficient strength has been reached, the strands are released, transferring the forces to the concrete. Pre-tensioning is typically used for precast concrete, where the forces can be restrained by fixed abutments located at each end of the stressing bed or carried by specially stiffened moulds.

Post-tensioning (PT) has been used in the construction industry to reduce slab thicknesses, increase the number of floors that can be built and allow the use of larger floor spans. Post-tensioning and pre-tensioning are widely used in bridge constructions.

Advantages of prestressed (Post-tensioned) floors

The primary advantages of Post-tensioned floors over conventional reinforced concrete in-situ floors are as follows:

Design

|

Performance

|

Service

|

Operation

|

Construction

|

Sustainability

|

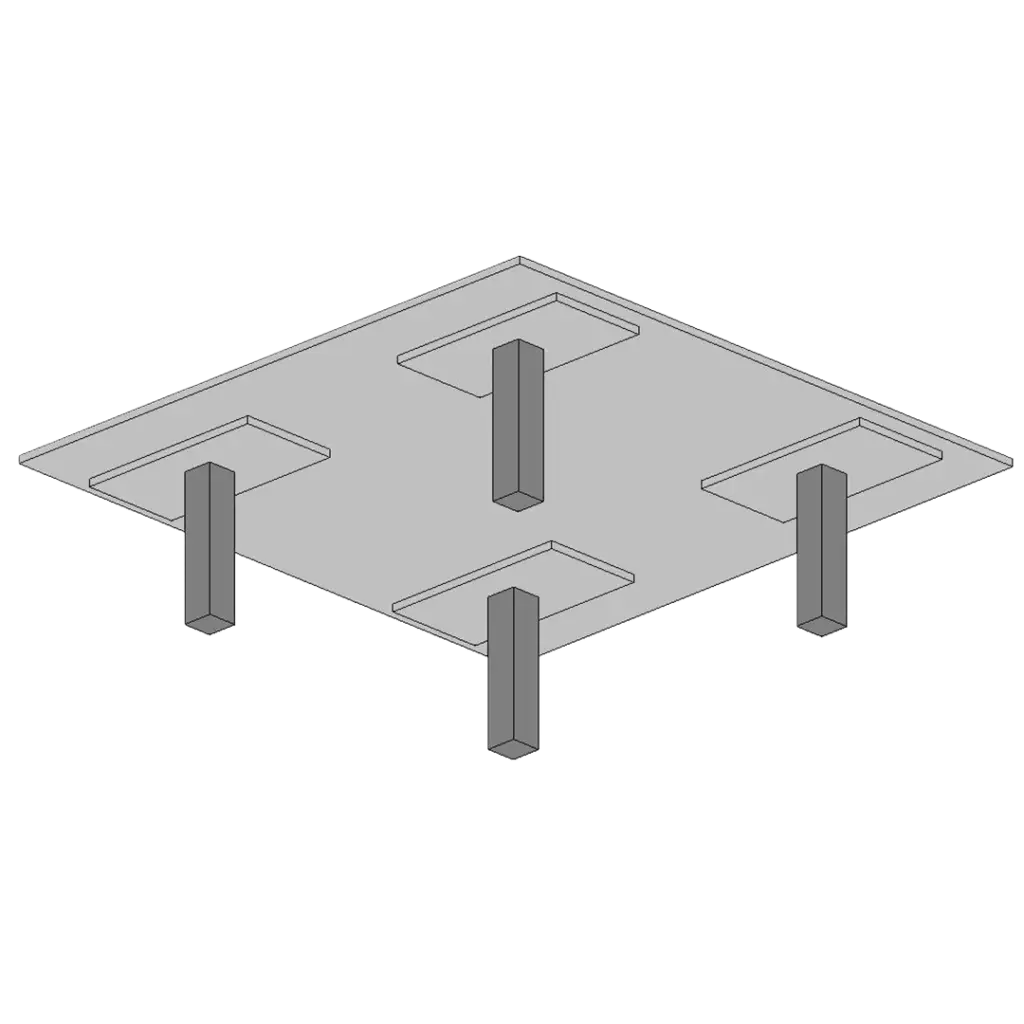

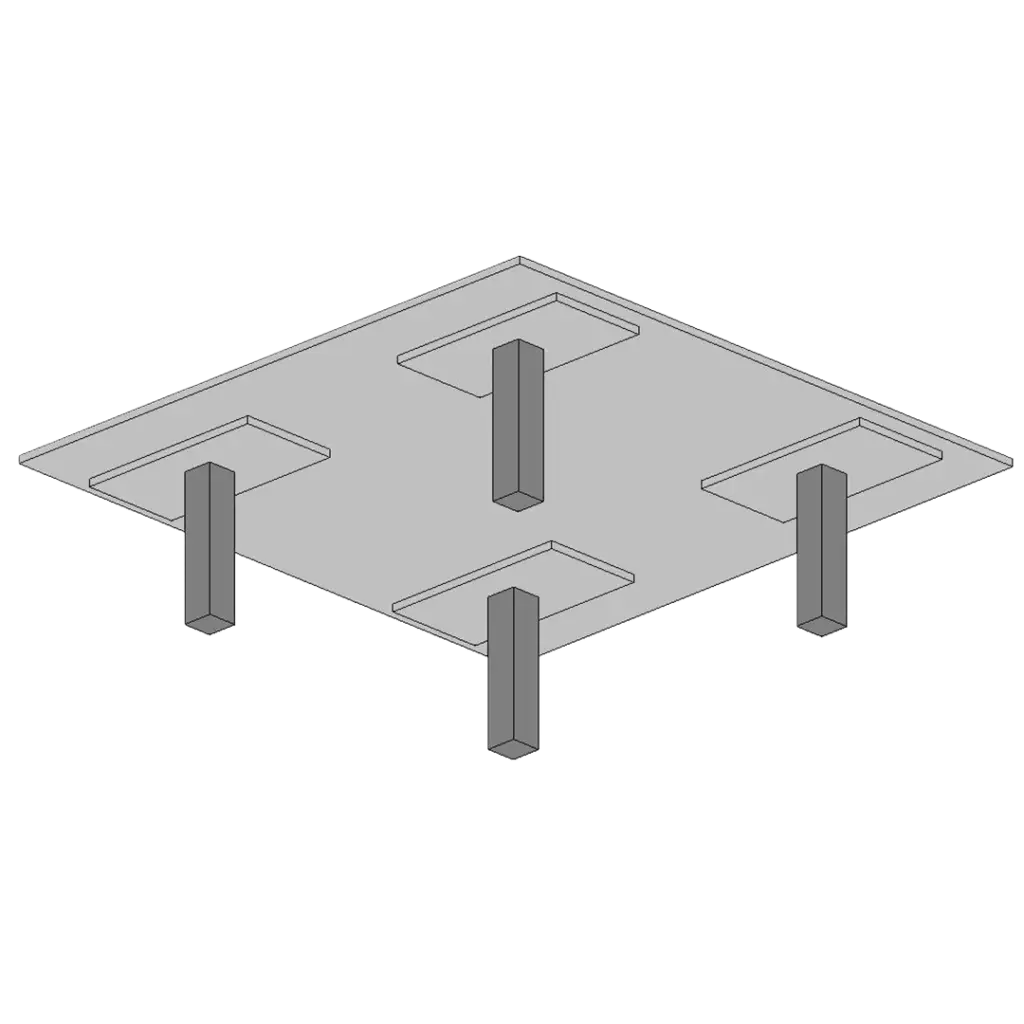

SOLID FLAT SLAB WITH DROP PANEL

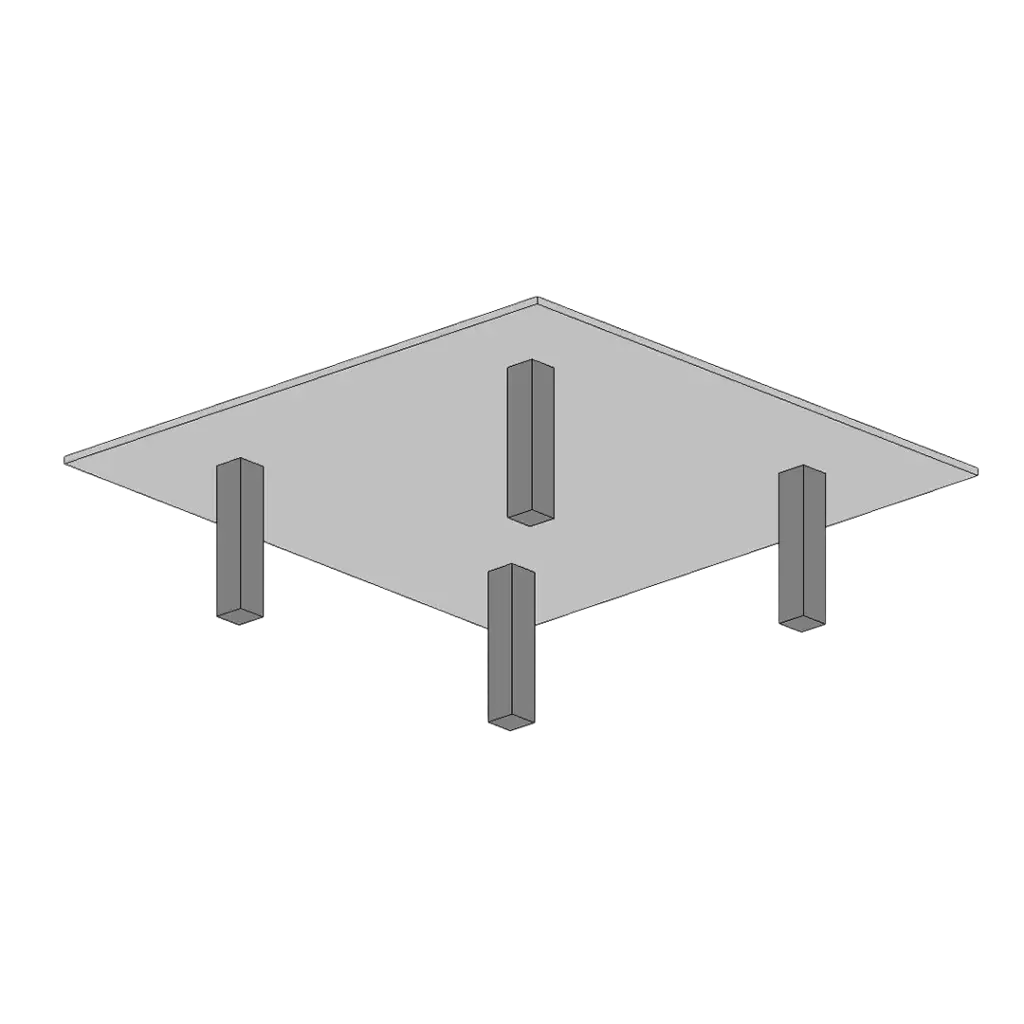

SOLID FLAT SLAB

SOLID FLAT SLAB WITH DROP PANEL

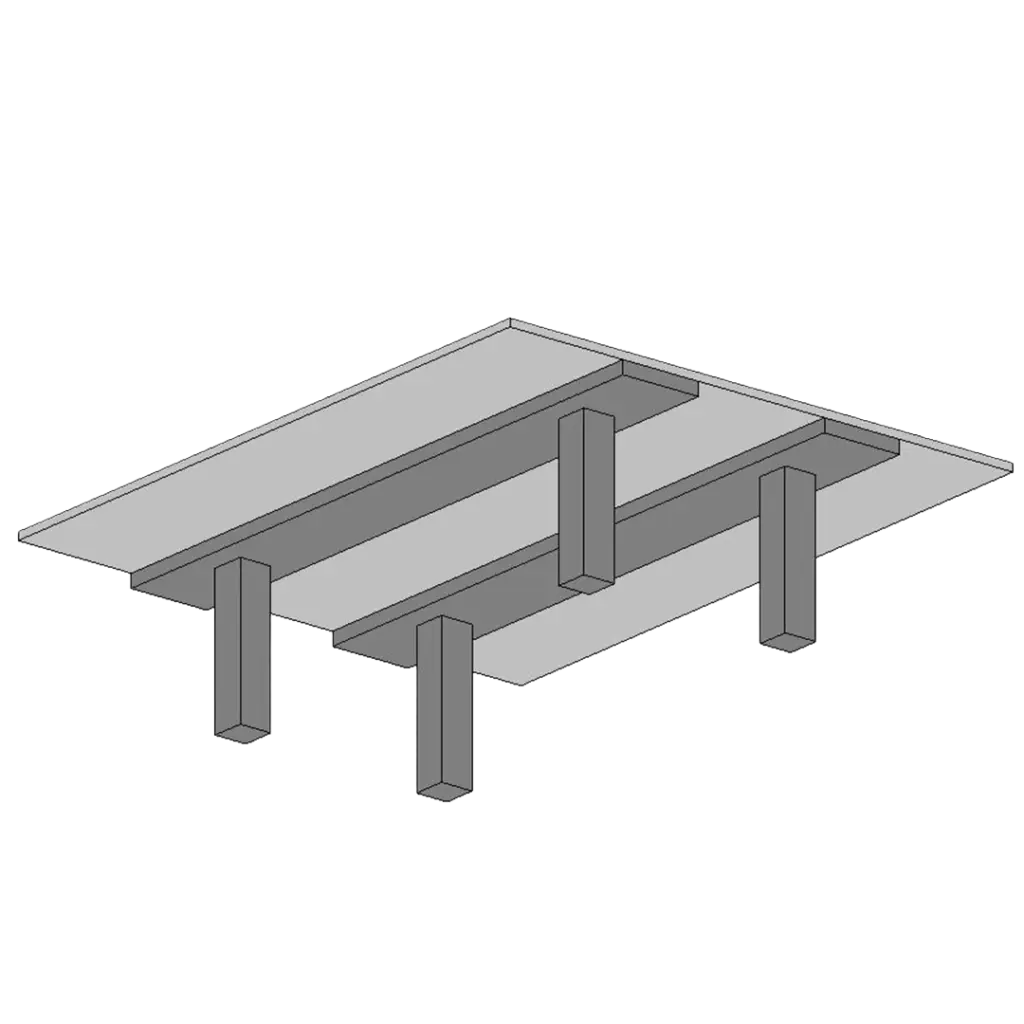

BROAD BEAM FLAT SLAB

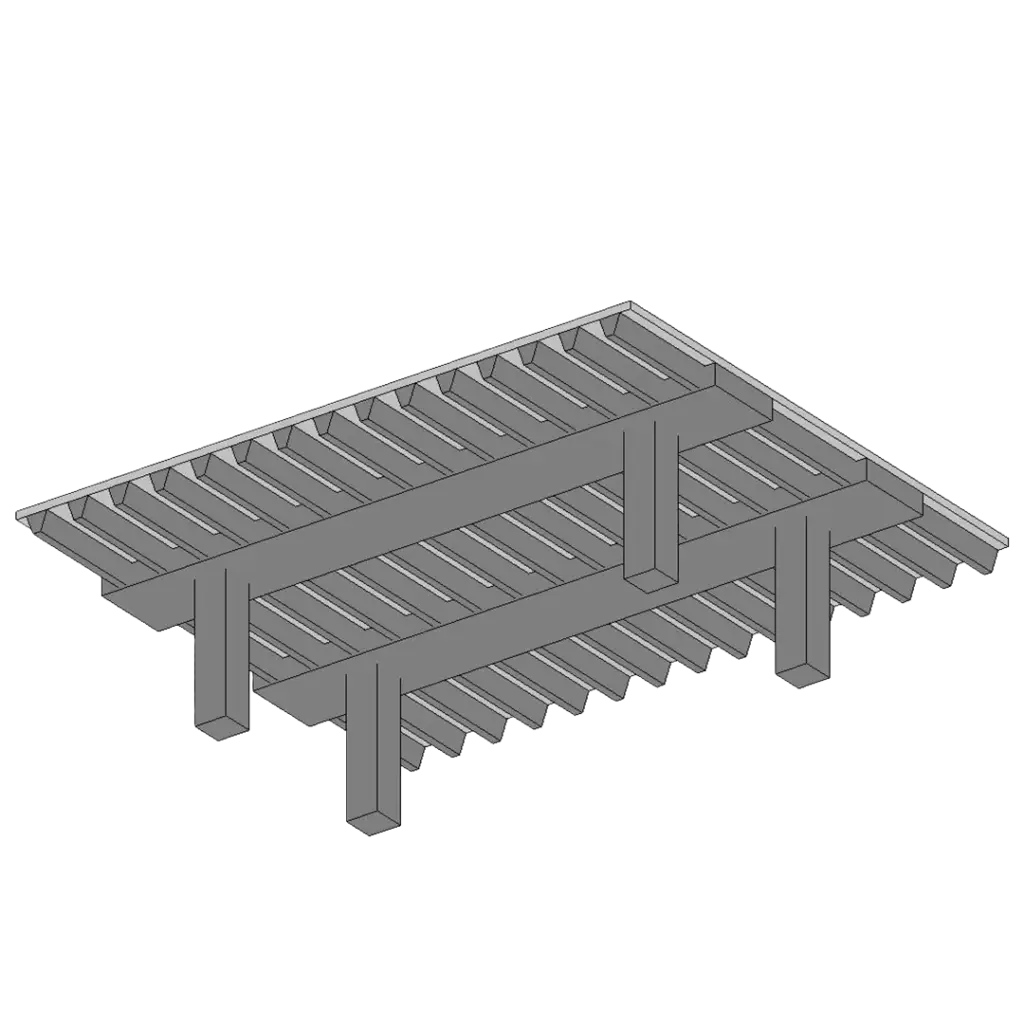

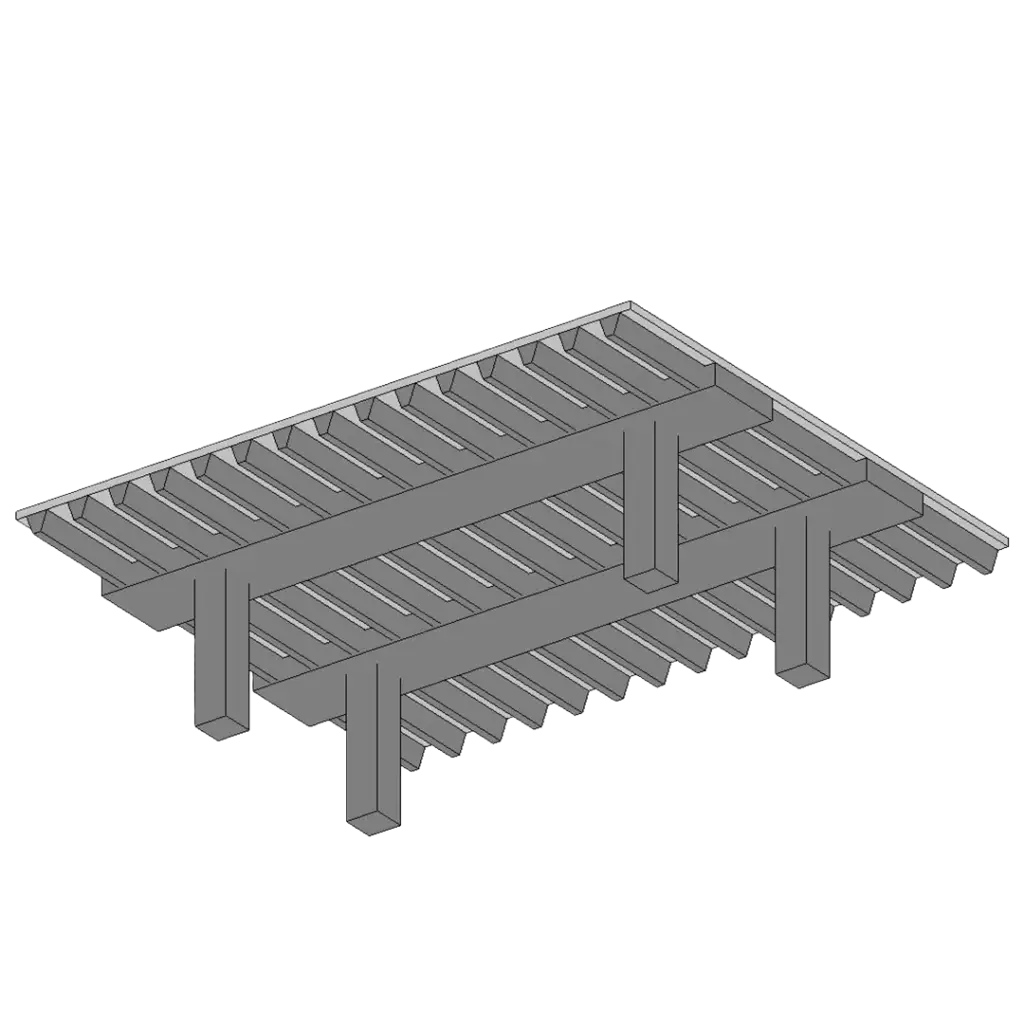

RIBBED SLAB

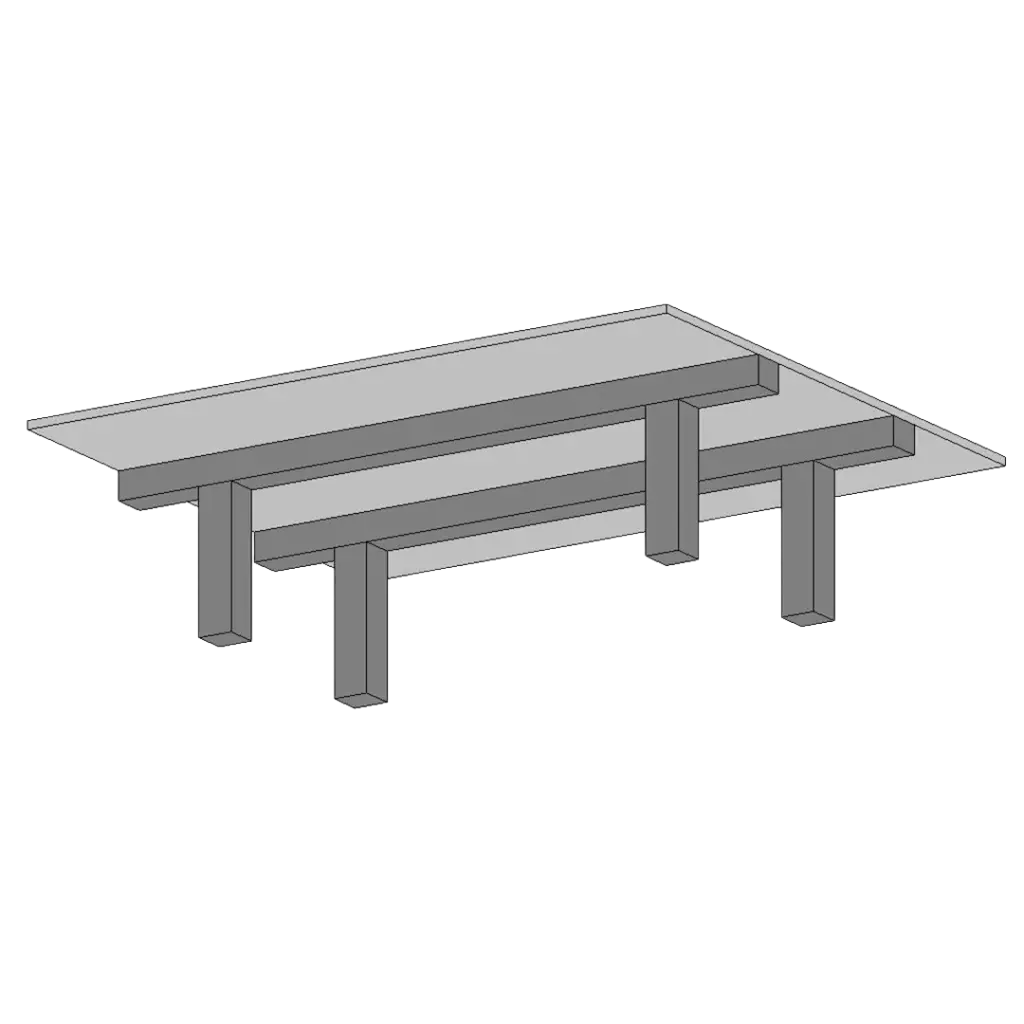

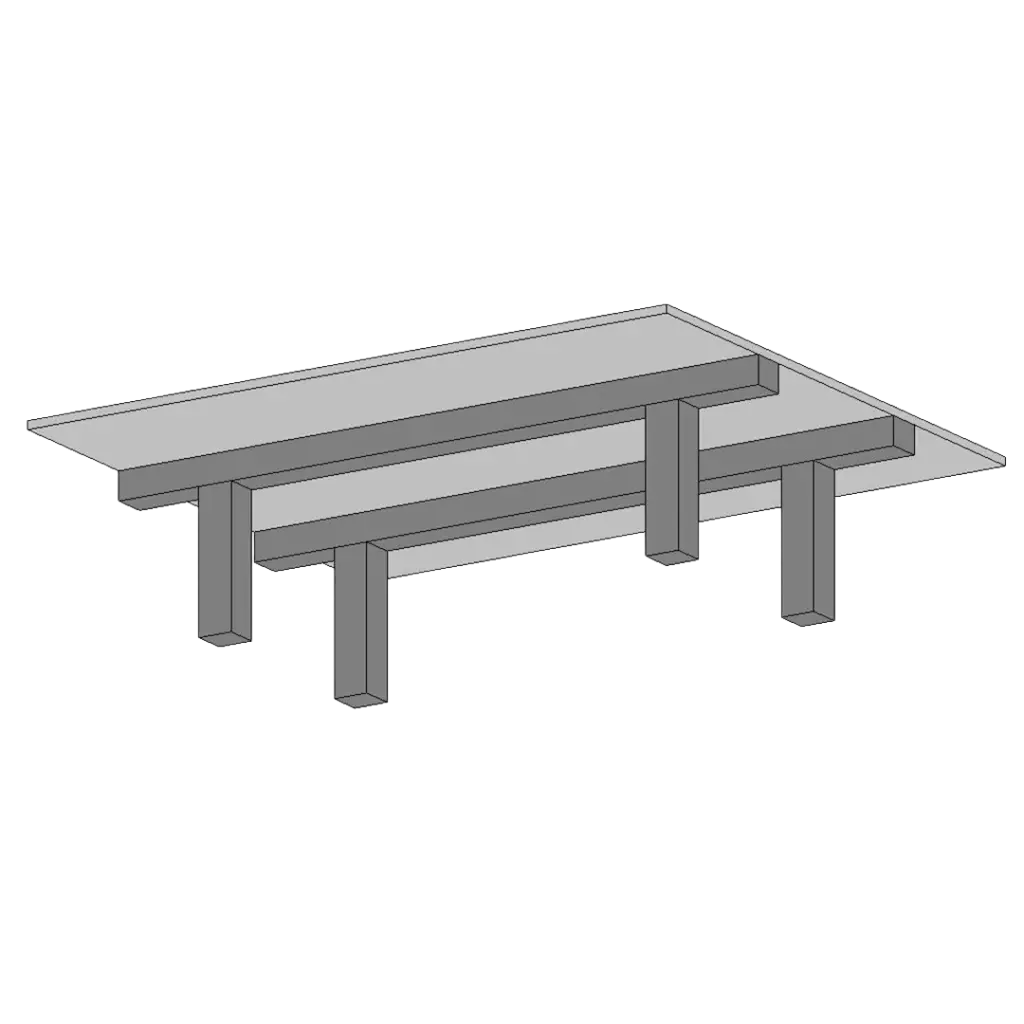

BEAM AND SLAB

Why our Design stands out

Performance-Centric Design

Seamless Design–Execution Alignment

Code-Compliant and Globally Accepted

Optimised & Practical Solutions

Our Post-tensioning Design Workflow

At Skyscraper Creators, our Post-tensioning design process combines technical depth, advanced software and a practical site understanding to deliver safe, efficient and constructible PT solutions. Each step is engineered to optimise performance while reducing cost and complexity.

Load & Span Assessment

We begin by evaluating structural loads, geometry and span requirements to determine whether PT is suitable and how best to integrate it within the design framework.

Cable Profiling & Layout

Tendon profiles are carefully modelled for optimal stress distribution, deflection control and anchorage positioning with attention to construction sequence and concrete behaviour.

Software-Based Design & Analysis

Advanced PT design tools such as RAPT and RAM are used to simulate performance, validate stresses and ensure code compliance (IS, BS, Eurocode, ACI).

Detailing & Stressing Planning

We produce precise shop drawings including tendon layouts, anchor positions, stressing sequences and elongation charts to support smooth on-site execution.

Coordination & Construction Support

Our team collaborates with engineers, contractors and PT vendors to ensure that detailing aligns with real-world site conditions enabling safe, efficient stressing and tensioning.